Have you ever wondered how puzzles are made? We go behind the scenes at a major puzzle manufacturer to show you the step-by-step process of how puzzles are designed, cut, and packaged.

The Fascinating Process of How Puzzles Are Made

The snap of interlocking pieces. The slow reveal of an image coming into focus. The surge of satisfaction from solving a complex riddle. Puzzles have a mysterious allure that pulls us in and awakens our curiosity.

Yet have you ever wondered about the actual process of how puzzles are designed and made? What kinds of intricate machinery or clever techniques are required to cut shapes into an initial blank space, eventually transforming it into an appealing and challenging mind-bender?

As an avid puzzler myself, I set out to uncover the secrets behind how puzzles are crafted. What I discovered was a fascinating combination of high-tech tools, handmade artistry, and mathematical precision.

Creating a great puzzle, it turns out, is not unlike solving one—it requires patience, logic, and a certain kind of creative thinking that can piece together something new out of small, disjointed parts.

Come along with me as I explore the cutting-edge (literally) of how puzzles are made. The journey may reveal more than a few surprises about this timeless pastime. Are you ready to see the pieces come together? Then let the puzzling begin!

Types of Jigsaw Puzzles

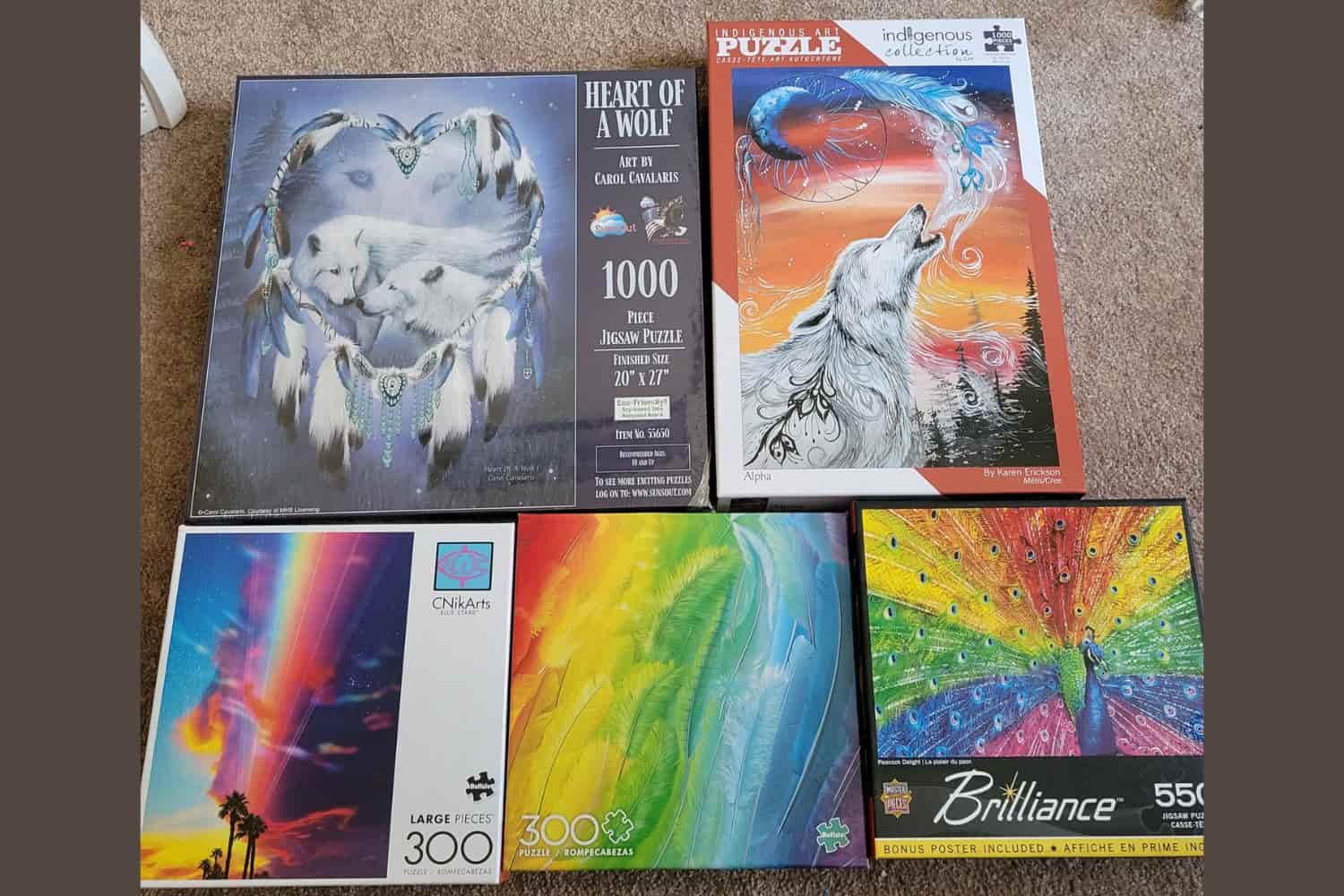

Before delving into the production process of jigsaw puzzles, let’s first clarify the various types of puzzles available. Jigsaw puzzles come in a wide array of shapes, sizes, and materials, each with its own unique characteristics:

Size:

The size of a puzzle encompasses both its physical dimensions and the number of pieces it contains. The possibilities are virtually endless. From compact A5-sized two-piece puzzles for little ones to large 500-piece puzzles ideal for families, and even colossal puzzles boasting a staggering 12,320 pieces, comparable in size to an American football field.

Shape:

While the typical image of a puzzle is that of a flat rectangle, the reality is more diverse. Puzzles are available in round, square, and even blob-shaped flat forms. Additionally, many puzzles are three-dimensional, transporting the puzzler into a new dimension. One can even embark on a puzzling journey through a Hogwarts-themed puzzle.

Material:

Puzzles can be differentiated by both the printed area and the backing material. While wooden puzzles are still crafted with expertise, the majority of puzzles today are printed on paper and affixed to cardboard.

In this blog post, we will focus on the manufacturing process of standard 1,000-piece puzzles backed with cardboard. It is noteworthy that while these puzzles are labeled as 1,000 pieces on the box, they typically consist of 38 by 27 pieces, totaling 1,026 pieces overall.

How Puzzles Are Made?

Decades ago, puzzles were painstakingly crafted by hand using tools like jigsaws to cut wooden or cardboard pieces. While some specialty puzzle makers continue this tradition, it has become far less common in modern times. Nowadays, most puzzles are mass-manufactured.

But have you ever wondered how exactly modern puzzles are made?

Step 1: Choosing the Perfect Image for Puzzle

Discover the secrets behind the captivating world of jigsaw puzzles by unraveling the mysteries of their creation process. At the heart of every puzzle lies the artwork, which serves as both the main attraction and the ultimate goal.

The possibilities are endless when it comes to selecting the perfect picture. From adorable kittens in a cozy workshop to picturesque country cottages or scenes from beloved animated movies, the choices are truly limitless.

In recent times, there has been a surge in the popularity of puzzles featuring mind-bending patterns, striking zebra stripes, or even solid colors. And for a truly personal touch, you can even create a puzzle using your own cherished photographs.

The most common sources for puzzle artwork can be found in original sketches designed by our in-house team or talented commissioned artists, recognizable images from the world of film and television, or iconic works of art.

Once the image is chosen, the transformation into a puzzle begins with a detailed sketch. Our dedicated team of designers works tirelessly to ensure that the graphics are not only suitable for the intended puzzle but also strike the perfect balance between challenge and engagement.

Next, the image is carefully scanned and meticulously adapted to a digital format using advanced editing software. At this stage, necessary enhancements such as color and contrast modifications are made, resulting in a visually appealing image that is also easy to puzzle.

Furthermore, this is also the opportune moment to design the box graphics, which will be the face of your puzzle. Once the design is approved, the cutting pattern can be expertly planned and executed, bringing your puzzle to life.

Embark on a journey of creativity and design as you explore the intricate process of selecting and transforming the perfect image into a masterpiece puzzle.

Step 2: Cut Pattern

A well-designed cut pattern is the key to an enjoyable jigsaw puzzle experience. Before production begins, the chosen image is carefully finalized and printed. Overlaying the image with a mapped pattern ensures that each piece can fit together seamlessly.

Top-quality puzzles take it a step further by ensuring that each piece is unique, guaranteeing that they can only fit in one specific way. A crucial consideration in creating the pattern is to ensure that cut lines do not obstruct any important details in the image.

With the approved design in hand, the manufacturing components are ready to be crafted, bringing your puzzle to life. Choose a puzzle with a meticulously designed cut pattern for a challenging and captivating experience.

Step 3: Making the Printing Plate

Puzzle manufacturers rely on a lithographic technique that involves creating a specialized plate to transfer ink onto the paper surface. This plate, typically made of plastic or metal, is carefully treated to ensure that the desired artwork elements are greased, while the blank areas remain moistened.

When an oil-based ink is applied to the plate, it will selectively adhere only to the greased portions.

This process works due to two essential principles: attracting like, where the oily ink is drawn to the greased parts, and the immiscibility of oil and water, preventing the ink from mixing with the dampened areas.

It’s worth noting that laser-printed puzzles have gained popularity in recent years, offering an alternative to the traditional method.

Step 4: Initial Quality Assurance Check

Following the initial printing, our quality control team carefully analyzes the puzzle for any required modifications prior to mass production.

Should we identify any discrepancies in color or image accuracy during this first run, our dedicated quality control experts promptly address the issues by adjusting colors and rectifying any mistakes found in the puzzle.

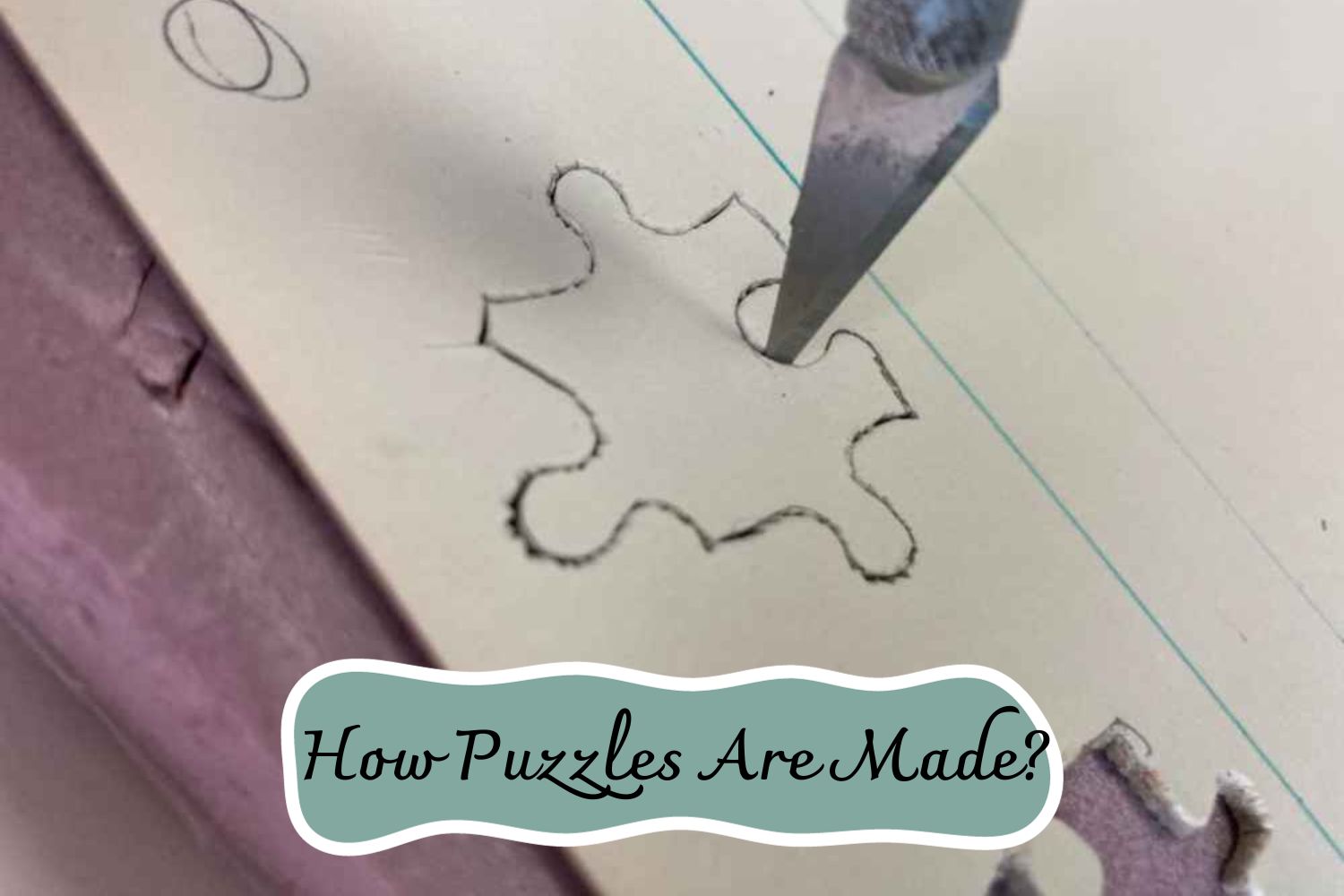

Step 5: Creating the Cutting Die: A Crucial Step in Jigsaw Puzzle Production

One crucial aspect of jigsaw puzzle production is the precision cutting of each piece. This meticulous process is carried out using a specially designed cutting die, similar to a large cookie cutter.

The cutting die is crafted to match the shape and dimensions of the desired puzzle pattern. This involves forming steel blades into the outline of each piece, which are then secured within a wooden mount.

Once all the manufacturing components are in place, the next step in creating jigsaw puzzles is printing.

Step 6: The Printing Process

To create the final image, the printing plate is carefully placed on a roller, which then applies the ink onto the paper. The type and quality of paper used can vary, but puzzle enthusiasts often opt for a matte type to eliminate any glare.

The printing process is completed one color at a time, following the CYMK system. As the paper moves from one printer to the next, each layer adds the colors cyan, magenta, yellow, and black until the complete image is formed.

Step 7: Mounting for Enhanced Presentation

In this step, we carefully mount the printed paper onto a sturdy backing, typically made of cardboard. We understand that the quality of cardboard can differ, as well as the adhesive used to securely bond it to the paper.

For optimal results, we aim for smooth cardboard that ensures a perfect fit. Once mounted, the prints are left to dry, which may take a few days.

Step 8: Puzzle Cutting with Precision

After the puzzle is dried, it is ready for the next crucial step: cutting. A specially prepared die is carefully mounted onto a cutting press.

With each puzzle passing beneath it, the press exerts an incredible force of approximately 700 tons, instantly dividing the puzzle into perfectly sized pieces. These pieces are then disassembled using a state-of-the-art scrambling machine.

To guarantee the utmost precision and quality, certain manufacturers utilize advanced camera technology during this phase. This ensures that every puzzle is accurately cut and that all its pieces are accounted for.

Step 9: Final Quality Check

Once the initial cut is completed, our diligent quality control team conducts a thorough examination. Their mission is to ensure that every cut is precise, identify any pieces that may be clinging to the punching tool, and detect any pieces that are still joined together. If any issues are discovered, the process is repeated until the puzzle attains perfection.

Step 10: Streamlined Packaging Process

After separating the puzzle pieces, they are carefully placed in a secure plastic bag and sealed. This bag is then inserted into the puzzle box. Finally, the boxes are efficiently shrink-wrapped and organized on pallets, ensuring they are prepared for shipping.

But don’t let their entertainment value fool you—puzzles offer more than just fun. They also provide a healthy workout for the brain. Experts believe that solving puzzles can stimulate various areas of the brain, much like trying to unravel a mystery. Engaging in puzzling activities can also help reduce stress levels. And of course, the satisfaction of placing that final piece in its rightful spot is simply unparalleled.

Perhaps this is why puzzles have stood the test of time as a timeless source of entertainment. While they have been around for hundreds of years, the Great Depression witnessed a significant surge in puzzle sales, as they offered an affordable way for people to enjoy themselves.

In conclusion, puzzles continue to captivate and challenge individuals across generations. Whether you embark on a puzzling journey alone or with friends and family, the joy and fulfillment it brings remain unmatched. So, why not grab a puzzle, immerse yourself in the process, and discover the magic of piecing together a world of possibilities?

The Materials Used for Puzzle-Making

Now that we understand the overall process of how puzzles are made, let’s take a closer look at the materials used. As mentioned previously, most modern puzzles are created using high-quality paper and cardboard.

But it’s not just any paper or cardboard—it has to have specific qualities to make a great puzzle. The paper must be thick enough to withstand repeated handling and not easily rip or tear. It also needs to have a smooth surface, making it easier for the pieces to interlock.

Cardboard is equally important as it provides the necessary support for the puzzle and prevents bending or warping. The cardboard used in puzzles is typically made from recycled materials, making them not only enjoyable but environmentally friendly as well.

In addition to these basic materials, some puzzle makers also use specialty items to enhance the puzzling experience. These can include things like foil, glitter, or even hidden objects in the design. Each of these elements adds an extra layer of creativity and complexity to the puzzle.

In conclusion, while puzzles may seem simple on the surface, a great deal of thought and care goes into selecting and preparing the materials used in their creation. From the image itself to the type of paper and cardboard, every component plays a crucial role in making a puzzle that is both challenging and enjoyable to solve. So, the next time you are working on a puzzle, take a moment to appreciate not just the design but also the materials used to bring it to life.

The Impact of Technology on Puzzle-Making

In recent years, technology has played a significant role in puzzle-making. While traditional methods of hand-cutting puzzles still exist, many puzzle makers have turned to more modern techniques that allow for faster production and greater efficiency.

One such method is laser cutting, which uses high-powered lasers to cut through materials with precision and accuracy. This technology has revolutionized the creation of wooden puzzles and has allowed for more intricate and detailed designs.

Another technology that has influenced puzzle-making is computer software. With the use of specialized programs, puzzle designers can create images specifically tailored for puzzles. These programs also allow for the creation of different shapes and sizes of pieces, making puzzles even more unique.

Technology has also transformed the way puzzles are sold and marketed. With the rise of online shopping, puzzles can now be easily purchased and shipped anywhere in the world. This has opened up opportunities for smaller puzzle makers to reach a wider audience.

In conclusion, technology has undoubtedly played a significant role in the evolution of puzzle-making. While traditional methods continue to exist, modern techniques have made it possible to create more complex and diverse puzzles that cater to different skill levels and interests. As technology continues to advance, it will be interesting to see how it further impacts the ever-evolving world of puzzles. So next time you pick up a puzzle and marvel at its design, remember the role technology has played in making it possible.

FAQs

Why is it called a jigsaw puzzle?

The term “jigsaw puzzle” originated from the tool used to cut puzzles into pieces, which had a similar design to the jigsaw hand saw. It became popular in the 1760s when John Spilsbury, a London mapmaker, began using them as educational tools. The name stuck and has been used ever since to describe puzzles that are cut into interlocking pieces.

How many puzzle pieces can a person assemble in an hour?

The number of puzzle pieces a person can assemble in an hour varies greatly depending on the individual’s skill level, the complexity of the puzzle, and their dedication to completing it. On average, someone with moderate experience can complete around 500-1000 pieces in an hour. However, some seasoned puzzlers can complete up to 1500 pieces in that same time frame.

Are there any benefits to solving puzzles?

Yes, there are numerous benefits to solving puzzles. Aside from being a fun and challenging activity, it has been linked to improving cognitive abilities such as memory, problem-solving skills, and visual-spatial reasoning. Puzzles also provide a way to relax and de-stress, making them a great activity for people of all ages. Furthermore, completing a puzzle can give a sense of accomplishment and boost self-esteem.

Can I create my own puzzles?

Yes, you can certainly try your hand at creating your own puzzles. With the use of specialized software and printing services, you can design and produce personalized puzzles with your own images and specifications. However, creating high-quality puzzles requires skill and expertise, so be prepared to invest time and effort into perfecting your craft. So go ahead and unleash your creativity by making your own unique puzzle designs! Remember, the possibilities are endless.

What’s the difference between a puzzle and a jigsaw puzzle?

The term “puzzle” is a broad term that can refer to any type of game or problem meant to be solved. A jigsaw puzzle, on the other hand, specifically refers to a type of puzzle that is made up of interlocking pieces and typically forms an image when completed.

In short, all jigsaw puzzles are puzzles, but not all puzzles are jigsaw puzzles. So next time you’re in the puzzle aisle, keep this distinction in mind as you browse through the various types of puzzles available.

Is there a trick to doing jigsaw puzzles?

While there is no specific trick to completing a jigsaw puzzle, there are some tips that can help make the process easier and more enjoyable. Some suggestions include starting with the edges of the puzzle, sorting pieces by color or pattern, taking breaks when needed, and having good lighting.

Ultimately, it’s all about finding what works best for you and developing your own strategy as you become more experienced with puzzle-solving. So grab a puzzle and start piecing it together! You never know, you may just find your new favorite hobby.

Conclusion

Ultimately, we can have a closer appreciation of the puzzles we enjoy solving after learning about the way they are made.

Through the skillful effort that goes into constructing these pieces of art, it is possible to produce multiple challenges that help us democracy with effective problem-solving and decision-making abilities.

It also reminds us when our minds eventually become helpless to questions, no matter how difficult they may seem; we must always remember that every second spent puzzling simply implies fortitude and resilience for any challenge ahead.

So next time you encounter a perplexing puzzle, take your time in connecting the dots – both literally and figuratively – and marvel at the complete picture made by carefully crafting these interlocking pieces.

Explore different kinds of puzzles available today and find yourself always ready to solve even the most mysterious ones!

Thanks for reading our article How Puzzles Are Made? If you want to know more information, visit our website here.

Read more:

How Often Do Puzzles Come With Missing Pieces?